One of the main challenges in the cultured meat industry is finding methods of mimicking meat musculature. It is very likely that the initial lab-grown meat products will be able to emulate processed meat products, such as minced meat, ground meat, and shredded meat. However, current research is working to develop and advance technologies that improve texture to create steak- or roast-like meat.

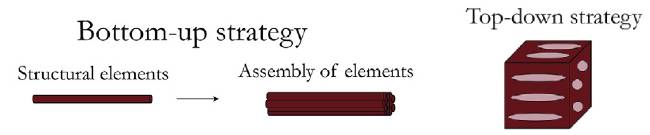

The most difficult meat analogue to produce is that which mimics meat musculature. According to Dr. Birgit Dekkers’ review in the Trends in Food Science and Technology in 2018, the current technology available to produce meat analogues that mimic muscle fibers can be separated into two categories: the bottom-up approach and the top-down approach. The bottom-up approach refers to assembling anisotropic structural elements. Anisotropic materials have physical properties that exhibit different values when measured in different directions. This is best visualized in wood, as it is stronger along the grain than across it. The bottom-up approach provides the most similarity between meat analogues and real animal products. The top-down approach structures biopolymer blends, composed of protein isolates and a solvent, using a force field. The main benefit of the top-down approach is that it is more easily scalable and uses resources more efficiently.

The bottom-up approach works by creating anisotropic structural elements that are later assembled into larger products. This approach follows the structural organization of muscles from the nanoscale to the macroscale. Components of the muscle’s structural organization includes myofibrillar proteins (used for muscle contraction), sarcoplasmic proteins (providing the enzymes needed for metabolic processes in the muscle cells), and connective tissue proteins (fibrous proteins providing the shape and protection of skeletal muscles).

The top-down approach typically attempts to mimic structure on a large-length scale rather than attempting to replicate authentic meat muscle structure. Essentially, this method uses technology to simulate the structure of meat, without actually creating the hierarchical structure of muscle tissue. This approach creates fibrous products by structuring and stretching biopolymer blends. Top-down methods use a force field to direct formation of biopolymer fibers.

Bottom-Up Approach

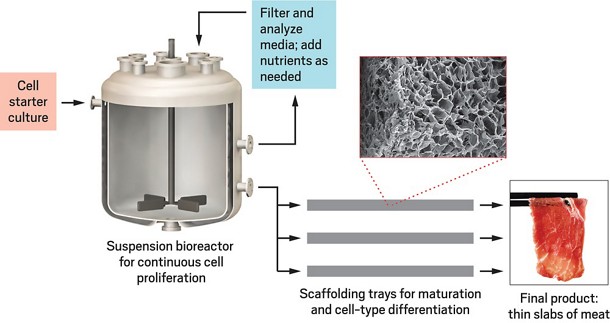

The Bioreactor Cultured Meat Approach:

- Myoblasts are harvested from a biopsy of skeletal animal muscle

- These cells are replicated in cell-culture (often using a serum-supplemented medium containing the necessary amino acids, lipids, vitamins, and salts) inside of a bioreactor

- When enough cells are produced, the muscle fibers are harvested and placed on a scaffold with anchor points to align the cells and replicate musculature

- After roughly 3 weeks the muscle fibers grow to 2-3cm and can be harvested

Necessary components: Precursor skeletal muscle cells, growth medium, and a bioreactor.

Outcome: Structural muscle fibers that can be 2-3cm long and less than 1mm thick.

Efficiency: This process is not easily scalable or very robust.

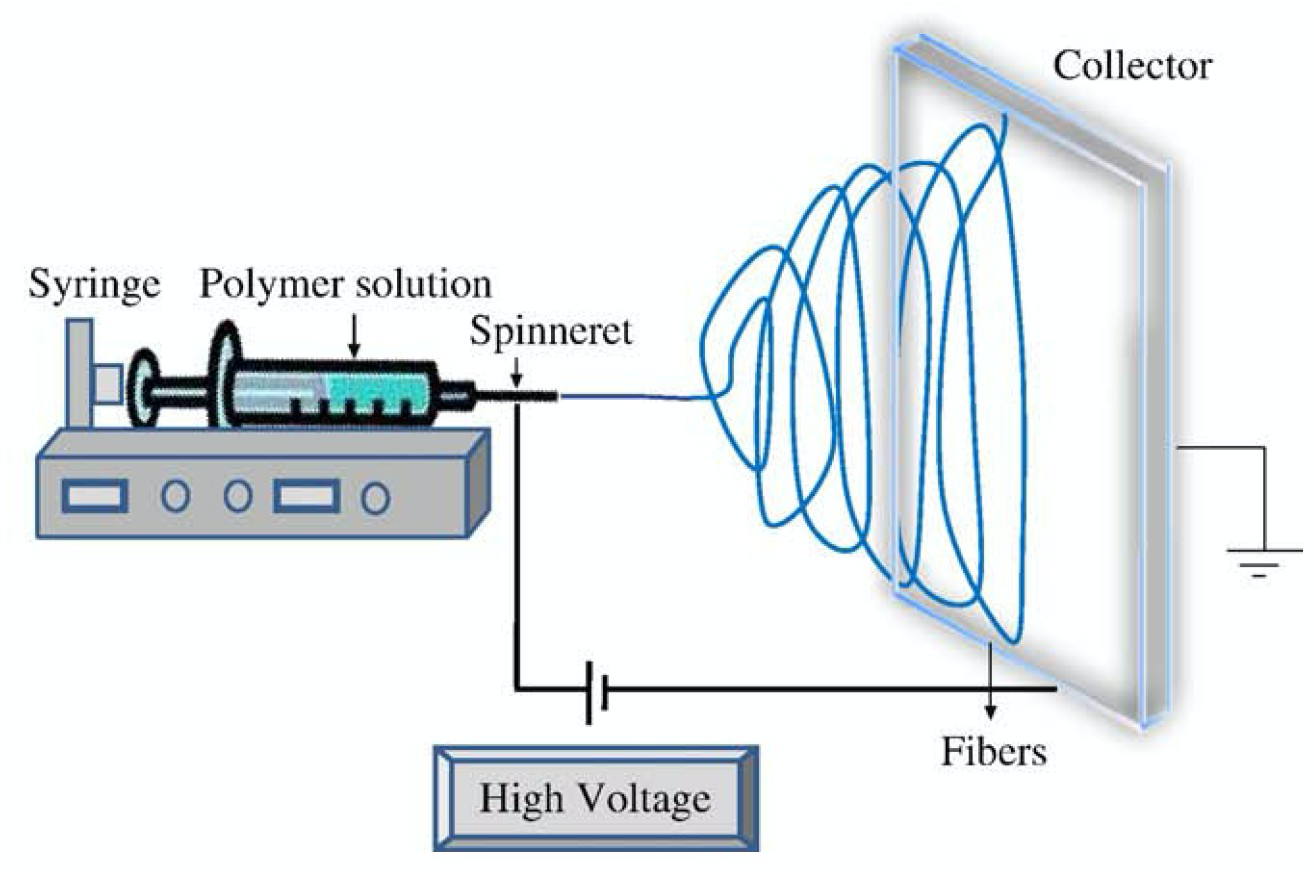

Electrospinning Approach:

- A biopolymer solution is made using a protein isolate (whey, collagen, albumin, or gelatin), solvent, and pH adjusters

- The conductive biopolymer solution is pushed through a spinneret that has an electric potential relative to a ground electrode

- The surface instability in the solution allows it to grow into thin fibers (~100nm in thickness) as a result of being drawn to the ground electrode

Necessary components: Biopolymer solution that has coiling properties instead of globular properties (hard to find in plant properties), an electrospinning set-up (barrel, high-voltage supply, ground electrode).

Outcome: Structural muscle fibers with a thickness on the scale of 100nm.

Efficiency: This process is quite robust; however, it is not easily scalable.

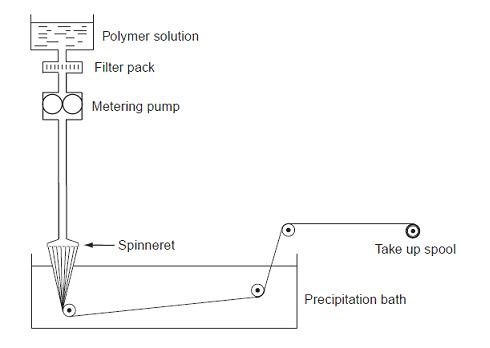

Wet-Spinning Approach:

- A biopolymer protein solution is made using a protein isolate and a solvent

- The solution is extruded through a spinneret at high speeds, allowing it to form thin fibers

- The extruded fibers are immersed in a bath with an anti-solvent

- This bath allows the proteins to precipitate out and solidify as a protein strands

- These strands of protein are spun onto a rotating collecting device

- This results in proteins stretched into filaments as thin as 20µm

Necessary components: Protein isolate and elastic biopolymer solution made with protein isolate, coagulation bath (bath containing a anti-solvent to allow solidification), wet-spinning set up (barrel, water bath, spinning nozzle, winding device).

Outcome: Strands of individual structural muscle fibers on a micrometer scale.

Efficiency: This process is quite robust, but not easily scalable.

Top-Down Approach

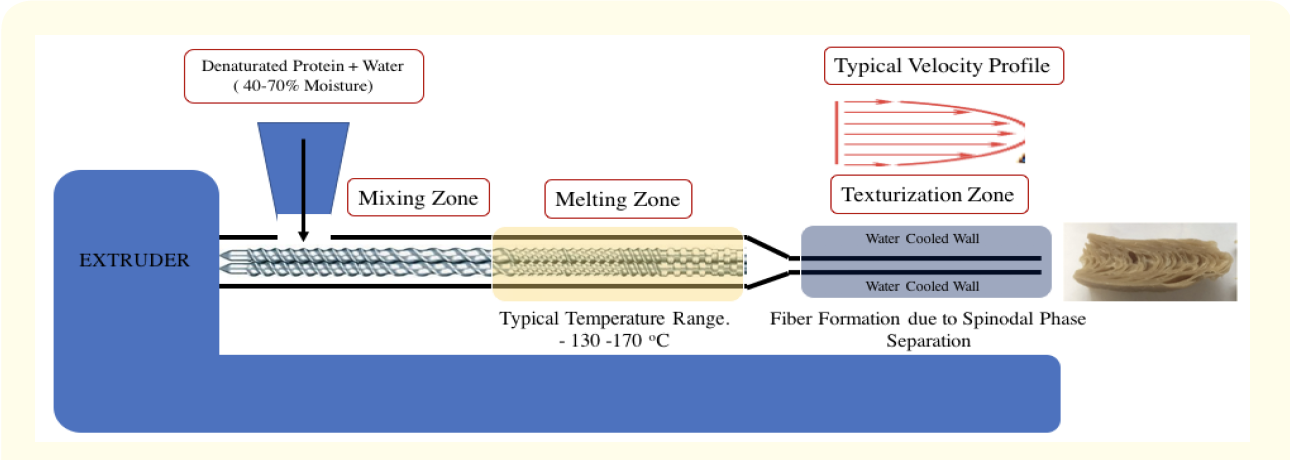

Extrusion

Extrusion is commonly used because it works with various protein blends and concentrates, which are much cheaper than protein isolates. There are two types of extrusion: low-moisture extrusion and high-moisture extrusion. Low-moisture extrusion uses flours or concentrates to create texturized vegetable proteins. High-moisture extrusion produces fibers with 50% water weight or higher moisture content.

- Protein solutions are molten inside a heated barrel

- The molten protein mixture flows through a small nozzle and gets aligned by inhomogeneous laminar flow. Laminar flow means that the protein mixture flows smoothly through the nozzles and the layers of the fluid pass each other without interruptions in their paths. As the fluid passing through the nozzle creates friction, the fluid in the center of the nozzle will flow faster than the peripheral regions. This is inhomogeneous flow, and this creates the thinly stretched fibers.

- The protein fibers are then cooled to prevent expansion

Necessary components: Mixture of defatted soy flour/protein concentrates/protein isolates and polysaccharide blends, and an extruder.

Outcome: Layered fibrous products on the microscale.

Efficiency: This process is very robust and easily scalable.

Summary

These different processing routes create fibrous products either through deforming or stretching the material. The bottom-up strategy has a higher potential to mimic meat more closely, whereas the top-down approach is more robust, scalable and more efficient. The methods reviewed above are the most common technologies used to improve the texture of lab-grown meat products. Many improvements and variations of these technologies are being used; however, the main difficulty is finding ways to scale up these technologies while retaining a low price point. As these structuring processes evolve, they should be able to refine the sensory properties of cultured meat.

References

Bomgardner, Melody. “The To-Do List for ‘Clean’ Meat.” Chemical & Engineering News,

https://cen.acs.org/business/food-ingredients/list-cleanmeat/96/i42. Accessed 13 Dec. 2020.

Dekkers, Birgit L., et al. “Structuring Processes for Meat Analogues.” Trends in Food Science

& Technology, vol. 81, Nov. 2018, pp. 25–36. ScienceDirect, doi:10.1016/j.tifs.2018.08.011.

Deora, Navneet Singh, and Madhuresh Dwivedi. Structuring Meat Analogues Using

Extrusion: An Insight. 2019, p. 3.

Kleszcz, Klaudia. Electrospinning. http://polybiolab.ippt.pan.pl/electrospinning.

Accessed 13 Dec. 2020.

Osen, Raffael, et al. “Effect of High Moisture Extrusion Cooking on Protein–Protein Interactions

of Pea (Pisum Sativum L.) Protein Isolates.” International Journal of Food Science & Technology,

vol. 50, no. 6, 2015, pp. 1390–96. Wiley Online Library, doi:https://doi.org/10.1111/ijfs.12783.

“The Manufacturing Process of Kevlar.” Kevlar, 4 Oct. 2016,

https://kevlarweb.wordpress.com/the-manufacturing-process-of-kevlar/.

Tuomisto, Hanna L. “The Eco-Friendly Burger.” EMBO Reports, vol. 20, no. 1, John Wiley & Sons, Ltd,

Jan. 2019, p. e47395. embopress.org (Atypon), doi:10.15252/embr.201847395.

Lab-Grown Meat Tackles the Looming Threat of Antibiotic Resistance

Lab-Grown Meat Tackles the Looming Threat of Antibiotic Resistance